Description

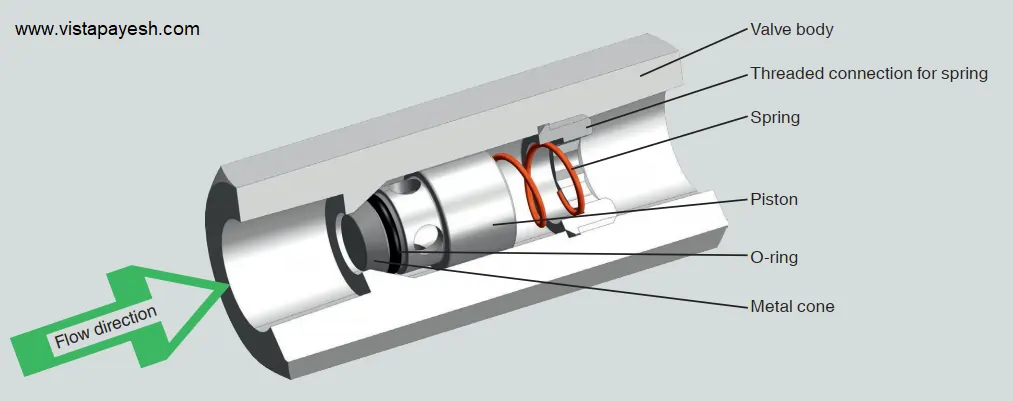

The model A check valves have been developed for the requirements of the process industry. The wetted parts are suited specifically for applications with natural gas and aggressive fluids, but also for water and hydraulic oil. The simple and robust design, with a safety factor of 4:1, enables model A check valves a wide spectrum of use. The valve design and the high-quality sealing materials ensure high durability and tightness. The sealing element (piston) has a double sealing system from an elastic O-ring and a metal cone. With any back pressure, the soft O-ring and then the sealing face of the metal cone prevent the reverse flow of the medium.

Applications

- Oil and gas industry, chemical and petrochemical industries, power plants

- Prevents the backflow of gases or liquids in measuring circuits

- For injection systems, actuator controls, test benches, hydraulic power packs

Special Features

- Safety factor 4:1 for pressurized parts

- One-piece, robust case construction prevents leaks

- High repeatability and bubble-tight sealing through self-centering piston

- Redundant sealing with O-ring and metal cone

- Leak-tested tightness in accordance with BS6755 /

- ISO 5208 leakage rate A

- Back stopped poppet minimizes spring stress

This principle of double sealing ensures reliable leak tightness.

Materials of Construction

| Item # | Part | Stainless Steel Valve |

| ۱ | Cap | ASTM A 276, TYPE 316 |

| ۲ | Seat* | Fluorocarbon Rubber |

| ۳ | Poppet | ASTM A 479, TYPE 316 |

| ۴ | Spring | ۳۱۶ Stainless Steel |

| ۵ | Body | ASTM A 276, TYPE 316 |

*Optional seat materials are available. See how to order section. Lubrication: Silicone Paste

Note: PTFE seated valves employ an additional PTFE coated 316 gaskets between the seat and the body and are distinguishable from elastomeric seated valves by the gap designed between the body and cap.

Specifications

| Standards used | |

| Design |

· ASME B16.34 valved – flanged, threaded and welding end · MSS SP-99, valves for measuring instruments · ASME B1.20.1, pipe threads, general purpose (inch) |

| Tests |

· API 598, valve inspection and testing · ISO 5208, pressure testing of metallic valves with leakage rate A · MSS SP-61, pressure testing of valves · DIN EN 12266-1, pressure tests, test procedures and acceptance criteria for industrial valves |

| Material requirements |

· NACE MR0175/ ISO 15156, use in H2S-containing in oil and gas production · NORSOK M-630, specification for use in pipelines |

| Marking | ASME B16.34, valves – flanged, threaded and welding end |

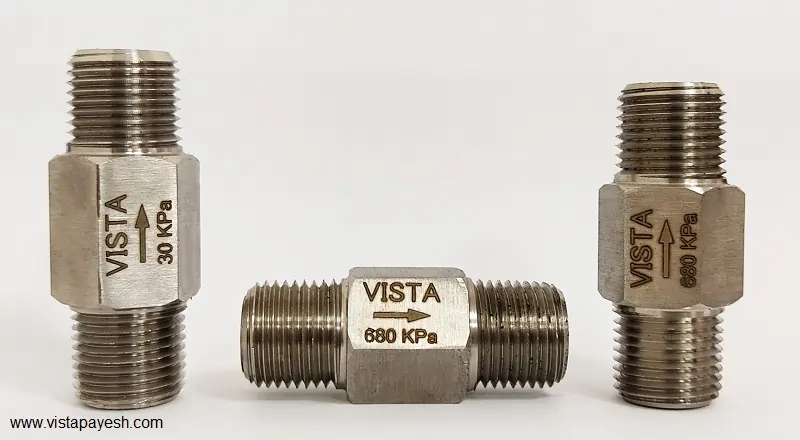

| Nominal pressure | ۱۰,۰۰۰ psi [690 bar] |

| Nominal width (DN) |

· ¼” · ۳/۸” · ½” · ¾” · ۱” |

| Valve bore size |

· ۵ mm [0.197 in] · ۶ mm [0.236 in] · ۱۰ mm [0.394 in] |

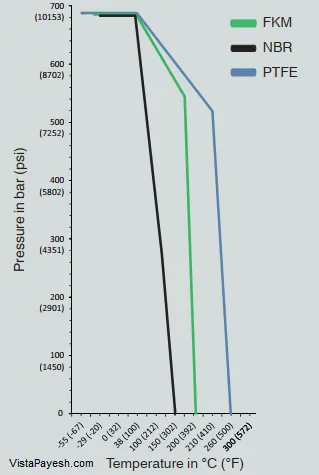

| Pressure-temperature limits | The limits for operating pressure and temperature depend on the version and the sealing material. |

| Connection type |

· Threaded connection per ISO 228-1, code G · Threaded connection per ANSI/ ASME B1.20.1, code NPT · Compression fitting with ferrule |

| Cracking pressure | ۲۰ psi [1.38 bar] ± ۳۰% |

| Features |

· Sealing through self-centering piston · Bubble-tight shut-off · Flow direction marked on valve body · Hydrostatically tested · ۱۰۰ % material traceability for wetted parts · Tight tolerances and the guided spring prevent the piston from jamming or seizing · Resistance against explosive decompression (AED sealing) · Other specification for cracking pressure (option) |

| Materials (Wetted Parts) | |

| Valve body and fittings, piston |

· Stainless steel 316L · Duplex F51 (1.4462) · Super Duplex F55 (1.4501) · Hastelloy C276 (2.4819) · Monel 400 (2.4360) · Stainless steel 6Mo (1.4547) · Alloy 625 (2.4856) · Alloy 825 (2.4858) |

| Spring |

· AISI 302 (1.4310) · Inconel X-750 |

| Temperature Range |

· NBR, temperature range: -29 … +120 °C [-20 … +248 °F] · FKM, temperature range: -46 … +180 °C [-51 … +356 °F] · PTFE, temperature range: -55 … +210 °C [-67 … +410 °F] |

Valve Design

| Sealing material | Max. permissible operating pressure in bar at temperature in ºC | Max. permissible operating pressure in psi at temperature in ºF | |

| Sealing | NBR | ۶۹۰ bar at 38 ºC | ۱۰,۰۰۰ psi at 100 ºF |

| ۲۷۶ bar at 120 ºC | ۸,۹۲۰ psi at 248 ºF | ||

| FKM | ۶۹۰ bar at 38 ºC | ۱۰,۰۰۰ psi at 100 ºF | |

| ۵۴۳ bar at 180 ºC | ۷,۸۷۵ psi at 356 ºF | ||

| PTFE | ۶۹۰ bar at 38 ºC | ۱۰,۰۰۰ psi at 100 ºF | |

| ۵۲۰ bar at 210 ºC | ۷,۵۴۲ psi at 410 ºF |