طراحی، پروفیل پره و منحنی عملکرد فن سانتریفیوژ

آوریل 18, 2020

دوره آموزشی عیب یابی به کمک آنالیز صدا و ارتعاشات در ماشین آلات صنعتی

سپتامبر 20, 2020

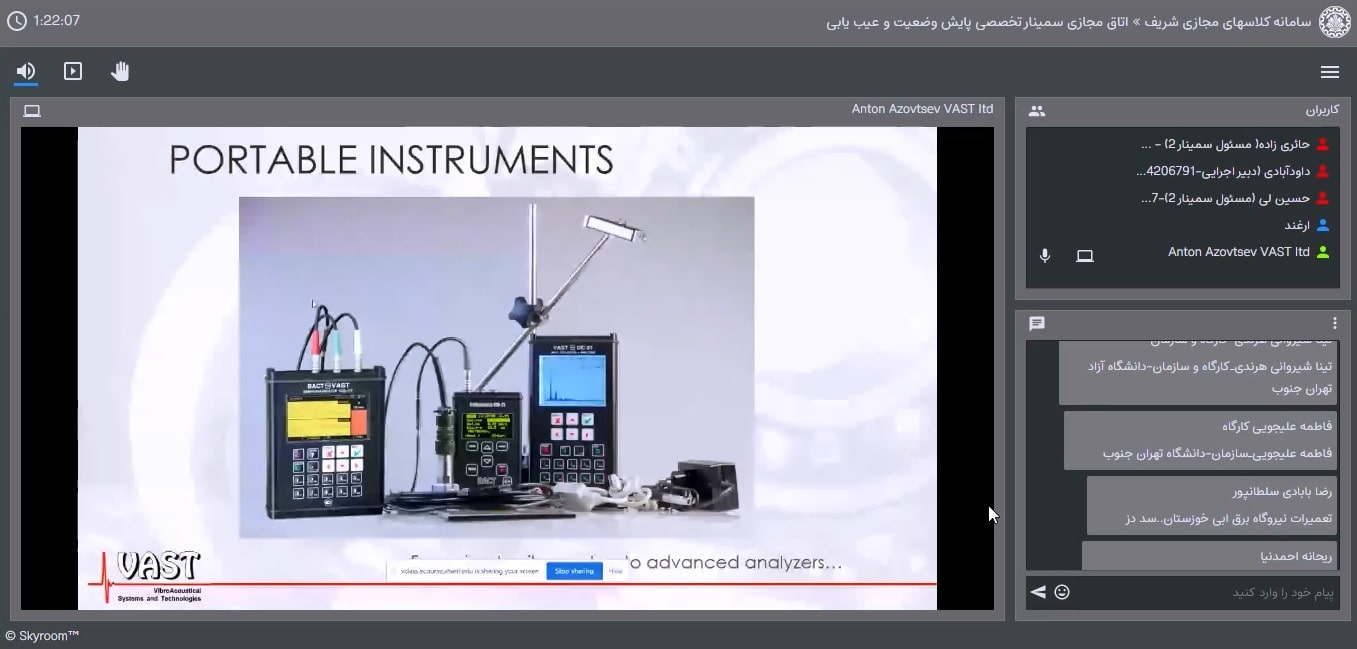

چهاردهمین کنفرانس تخصصی و بین المللی پایش وضعیت و عیب یابی با حضور شرکت ویستا پایش راد در تاریخ سه شنبه 28 مرداد 1399، به صورت مجازی برگزار شد خواهد بود. محل برگزاری این کنفرانس دانشگاه صنعتی شریف (سامانه کلاسهای مجازی) بود که در ابتدا با ارائه معرفی شرکت و محصولات و خدمات شرکت توسط مهندس جهان شاهلو همراه بود. پس از ایشان آنتوان آزوتوف از شرکت همکار در کشور روسیه ارائه ای خدمت حاضرین کنفرانس انجام دادند.

Vibration Analysis

Even in good condition, machines generate vibrations. Many such vibrations are directly

linked to periodic events in the machine’s operation, such as rotating shafts, meshing gearteeth,

rotating electric fields, and so on. The frequency with which such events repeat often gives

a direct indication of the source and thus many powerful diagnostic techniques are based on

frequency analysis. Some vibrations are due to events that are not completely phase locked

to shaft rotations, such as combustion in IC (internal combustion) engines, but where a fixed

number of combustion events occur each engine cycle, even though not completely repeatable.

As will be seen, this can even be an advantage, as it allows such phenomena to be separated

from perfectly periodic ones.

چهاردهمین کنفرانس پایش وضعیت و عیب یابی

Other vibrations are linked to fluid flow, as in pumps and gas

turbines, and these also have particular, quite often unique, characteristics. The term ‘vibration’

can be interpreted in different ways, however, and one of the purposes of this chapter is to

clarify the differences between them and the various transducers used to convert the vibration

into electrical signals that can be recorded and analysed.

One immediate difference is between the absolute vibration of a machine housing and the

relative vibration between a shaft and the housing, in particular where the bearing separating

the two is a fluid film or journal bearing.